Why Choose a Pleated Filter Bag for Industrial Filtration?

2025-09-24

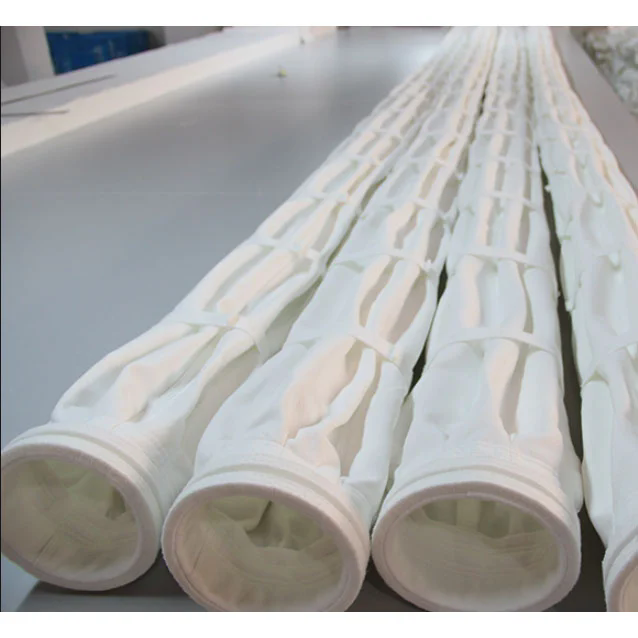

Filtration is the backbone of many industries, from pharmaceuticals and chemicals to food processing, cement, mining, and power generation. One of the most effective tools in modern dust collection and liquid-solid separation is the Pleated Filter Bag. Unlike conventional filter bags, pleated versions are engineered to deliver higher filtration surface area, longer service life, and better efficiency under demanding operating conditions.

A pleated filter bag is designed with folds or pleats that dramatically increase the available filter media surface within the same housing dimensions. This structural advantage means more particles can be captured without enlarging the filtration system itself. For plants seeking improved efficiency without expanding equipment footprint, this solution stands out as a cost-effective upgrade.

Core Features That Define Performance

To evaluate the strength of a pleated filter bag, it is important to consider its measurable technical parameters. Below is a reference table that demonstrates the professional specifications industries usually require:

| Parameter | Typical Range/Specification |

|---|---|

| Filter Media | Polyester, Polypropylene, PTFE, Aramid, PPS |

| Filtration Efficiency | 99% or higher (submicron particle capture possible) |

| Operating Temperature | -20°C to 260°C (depending on media type) |

| Air-to-Cloth Ratio | Up to 2–3 times higher than traditional bags |

| Surface Area | 1.5x – 3x more than standard filter bags |

| Length Options | 500mm – 2000mm |

| Diameter Range | 120mm – 160mm (customized available) |

| End Cap Materials | Galvanized steel, stainless steel, or polymer |

| Cleaning Method | Pulse-jet or reverse air compatible |

| Applications | Cement plants, food processing, chemicals, pharma |

This list highlights not just the versatility but also the adaptability of pleated filter bags. Their ability to endure harsh temperatures, resist chemical degradation, and fit into existing housings without costly retrofits makes them a practical choice.

But understanding specifications alone is not enough. The deeper question is: How do pleated filter bags translate into operational advantages for industries worldwide?

How Do Pleated Filter Bags Improve Industrial Efficiency?

The efficiency of industrial processes depends heavily on how effectively dust or unwanted particles are removed from air streams, liquids, or powders. Pleated filter bags address this need through three primary mechanisms: increased surface area, optimized airflow, and durable filtration media.

Increased Surface Area = Higher Dust Holding Capacity

With pleats carefully arranged, the bag exposes two to three times more filtration surface compared to a smooth cylindrical filter. This increased surface area translates into higher dust holding capacity, meaning the filter can operate longer before requiring replacement or cleaning. Industries benefit through reduced downtime, lower maintenance costs, and uninterrupted production.

Optimized Airflow Dynamics

Air-to-cloth ratio is a crucial metric. Traditional filter bags often restrict airflow when particle loading increases. Pleated filters, however, maintain airflow efficiency because of their extended surface area. This ensures that fans and blowers do not need to overwork, reducing energy consumption and prolonging equipment life.

Durability in Harsh Environments

Pleated filter bags are built with advanced polymers and treated fibers that withstand extreme temperatures, abrasive particles, and chemical exposure. For example:

-

Aramid and PPS pleated bags are ideal for cement kilns where gases exceed 200°C.

-

PTFE-coated polyester ensures hydrophobic resistance in pharmaceutical or food applications.

-

Polypropylene pleated bags offer excellent resistance to acids and alkalis in chemical processing.

The engineering behind pleated filters also includes rigid internal cages or support cores that prevent collapse, even under high differential pressures. This structural stability is what allows pleated bags to last longer than their conventional counterparts.

What This Means for Industry Leaders

-

Reduced operational costs through fewer change-outs.

-

Improved compliance with environmental regulations by capturing finer particulates.

-

Enhanced safety for workers exposed to airborne dust or contaminants.

-

Scalable integration since most housings can accept pleated bags without modification.

When we ask: How do pleated filter bags improve efficiency? The answer lies in measurable cost savings, environmental benefits, and reliability—all achieved by leveraging smarter filtration engineering.

Why Are Pleated Filter Bags the Preferred Choice Across Industries?

Every industry has unique requirements, yet pleated filter bags consistently emerge as the preferred solution. This raises the important question: Why have pleated filter bags become the standard for many global operations?

Consistency in Performance

Industries like pharmaceuticals and food processing demand clean environments where cross-contamination must be avoided. Pleated filter bags, thanks to their fine filtration and easy cleaning design, provide consistent results batch after batch.

Environmental Compliance

Regulatory agencies impose strict emission limits. For cement plants, power stations, and chemical facilities, exceeding dust emission standards can lead to hefty fines and reputational damage. Pleated filter bags capture even submicron particles, ensuring businesses remain compliant.

Cost-Benefit Advantage

While pleated filter bags may initially cost more than traditional bags, their extended service life, reduced energy demand, and minimal maintenance deliver a far better return on investment. For industries operating 24/7, these advantages accumulate into substantial savings.

Applications Across Sectors

-

Cement Industry: Handles clinker dust, kiln gases, and abrasive particulates.

-

Food & Beverage: Ensures hygienic processing without contamination.

-

Pharmaceuticals: Protects cleanrooms and production batches from fine dust.

-

Chemicals: Resists aggressive vapors and corrosive environments.

-

Mining & Power Generation: Manages high dust loads in large-scale facilities.

Answering the Why

So, why choose pleated filter bags? Because they solve three fundamental industrial challenges: efficiency, compliance, and reliability. They represent a technology that aligns cost savings with sustainability, making them an integral part of modern industrial infrastructure.

What Should You Consider Before Choosing a Pleated Filter Bag?

Selecting the right pleated filter bag involves more than checking dimensions. Industries must evaluate the operating environment, dust characteristics, airflow requirements, and cleaning systems to ensure compatibility.

Key Considerations:

-

Temperature Range – Match the media type to expected operational heat levels. Polyester may suffice for moderate ranges, while aramid or PTFE is essential for high-heat environments.

-

Chemical Resistance – In corrosive environments, polypropylene or PTFE coatings deliver protection.

-

Air-to-Cloth Ratio – Ensure the bag design maintains efficient airflow without overloading.

-

Filter Housing Compatibility – Although pleated bags often fit into existing housings, end cap design and sealing must align with system specifications.

-

Cleaning Mechanism – Pulse-jet cleaning systems benefit most from pleated bags, as the pleats shed dust effectively under reverse air pressure.

Practical Guidance for Buyers

A plant manager must ask:

-

What type of dust or particles are we filtering?

-

How often can we afford maintenance shutdowns?

-

What are our regulatory emission limits?

-

How do energy costs impact our long-term operating expenses?

Answering these questions ensures the chosen pleated filter bag not only fits but also delivers the expected performance.

Frequently Asked Questions (FAQs)

Q1: What is the difference between a pleated filter bag and a traditional filter bag?

A pleated filter bag has folds that increase the filtration surface area, allowing it to capture more particles and operate longer, while a traditional bag has a smooth cylindrical surface with limited dust-holding capacity.

Q2: How long does a pleated filter bag typically last?

Depending on the operating environment and cleaning system, a pleated filter bag can last two to three times longer than a conventional filter bag, reducing replacement frequency and costs.

Q3: Why is a pleated filter bag considered energy efficient?

Because pleated bags maintain airflow with less resistance, fans and blowers consume less energy, lowering overall power consumption in dust collection systems.

Why SMCC Pleated Filter Bags Are the Smarter Choice

Across industries, pleated filter bags represent a proven solution for reducing costs, improving efficiency, and maintaining regulatory compliance. From cement and chemicals to pharmaceuticals and food processing, their versatility makes them an ideal choice for diverse applications.

SMCC has developed pleated filter bags with advanced materials and precise engineering to meet these evolving demands. With consistent performance, durability, and customization options, SMCC products deliver reliability where it matters most.

If your operation is seeking long-term savings, higher efficiency, and improved compliance, contact us today to learn more about how SMCC pleated filter bags can optimize your filtration system.