Why Is Twill Glass the Preferred Choice for Advanced Composite Applications?

2025-11-13

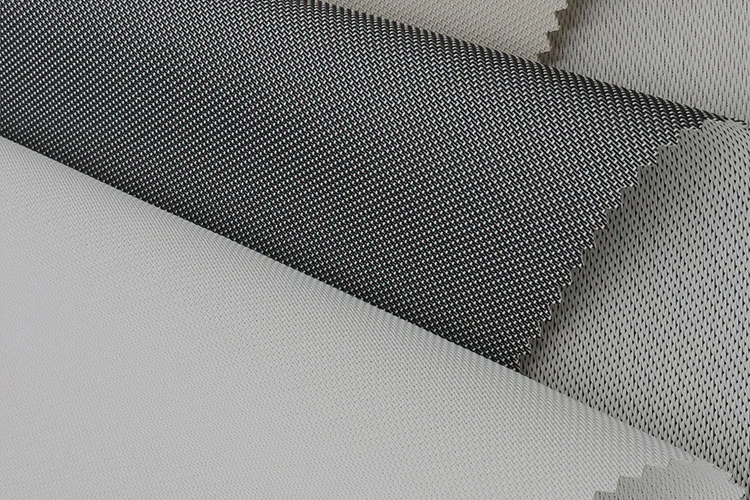

When it comes to composite reinforcement materials, Twill Glass stands out for its unique weave pattern, strength, and flexibility. As a leading manufacturer, Guangzhou Hande New Materials Co., Ltd. specializes in producing high-performance Twill Glass that meets the demanding needs of various industries such as aerospace, automotive, marine, and construction. Its superior drapability, excellent surface finish, and balanced strength-to-weight ratio make it one of the most sought-after fiberglass fabrics in the global market.

What Is Twill Glass and How Does It Work?

Twill Glass refers to a type of fiberglass fabric woven using a twill weave pattern, where each warp thread crosses over and under two or more weft threads in a diagonal sequence. This creates a distinct diagonal rib appearance, improving flexibility and formability compared to plain weave fabrics. The twill weave allows better draping over complex surfaces, making it ideal for molded parts and high-performance components.

The structure of Twill Glass provides:

-

High conformability to curved surfaces

-

Enhanced mechanical strength

-

Smoother appearance with fewer surface distortions

-

Improved resin flow during lamination

Key Technical Parameters of Twill Glass

| Property | Specification | Description |

|---|---|---|

| Weave Type | Twill 2/2 or 4/4 | Defines diagonal pattern and flexibility |

| Yarn Type | E-glass / S-glass | Ensures thermal and chemical resistance |

| Weight | 200–600 g/m² | Determines thickness and mechanical strength |

| Width | 1000–2000 mm | Customizable according to application |

| Tensile Strength | ≥ 3400 MPa | Provides excellent load-bearing capacity |

| Temperature Resistance | Up to 550°C | Suitable for high-heat environments |

The Role and Benefits of Twill Glass

-

Excellent Strength and Durability – Twill Glass offers superior tensile and impact resistance compared to plain weave fabrics, making it suitable for load-bearing composite parts.

-

Superior Aesthetic Finish – The diagonal weave produces a smooth, visually appealing surface, perfect for visible composite components.

-

Enhanced Resin Impregnation – Its unique weave structure allows even resin distribution, reducing voids and improving part quality.

-

Versatility in Use – It is compatible with epoxy, polyester, and vinyl ester resins for use in various industrial and consumer products.

Application Fields of Twill Glass

| Industry | Application | Benefits |

|---|---|---|

| Aerospace | Aircraft panels, radomes | Lightweight and high strength |

| Automotive | Body panels, structural reinforcements | Smooth finish, corrosion resistance |

| Marine | Hulls, decks | Excellent resistance to moisture and impact |

| Construction | Reinforced panels, architectural elements | Long lifespan and stability |

| Sports Equipment | Bicycles, helmets, skis | High flexibility and low weight |

What Makes Twill Glass Important for Modern Industries?

Twill Glass plays a crucial role in modern composite manufacturing due to its combination of strength, flexibility, and aesthetic appeal. Its ability to conform to complex shapes without wrinkling or distortion allows engineers to design lightweight yet strong products. Moreover, it reduces production time and resin consumption, leading to cost-effective fabrication.

My Professional Insights

Q1: Why do I prefer Twill Glass for my composite projects?

A1: Because Twill Glass provides excellent drapability and strength. When I design complex shapes, it adapts perfectly without compromising structural integrity.

Q2: What advantages have I observed when using Twill Glass from Guangzhou Hande New Materials Co., Ltd.?

A2: Their Twill Glass maintains consistent quality, precise weaving, and high resin compatibility, which significantly improves my production efficiency.

Q3: How do I ensure the best results when applying Twill Glass?

A3: I always choose the right fabric weight and weave type for my project. With proper resin application and curing, the results are smooth, durable, and professional-grade.

Importance and Effectiveness

Using Twill Glass not only enhances product appearance but also improves performance under mechanical and environmental stress. Its flexibility makes it ideal for shaping around contours, while its mechanical strength ensures durability even in challenging environments. In industries prioritizing lightweight materials with superior strength, Twill Glass has become an indispensable solution.

Conclusion

As technology and design demands continue to rise, Guangzhou Hande New Materials Co., Ltd. remains committed to providing high-quality Twill Glass solutions for global industries. Our products combine precision weaving, durability, and exceptional performance to meet your composite material needs.

If you are looking for reliable Twill Glass with professional customization and consistent quality, contact us today to learn how we can help enhance your next project.